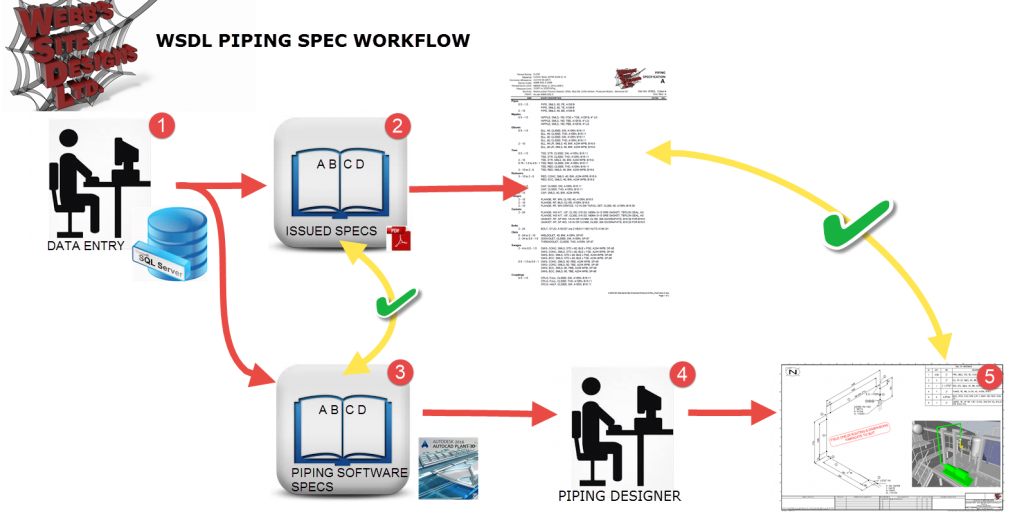

As part of WSDL’s goal of “single source data”, and “design synergy through the utilization of a well-oiled software machine”, we have developed a piping specification workflow that takes steps to achieve this end goal. Shown below is a high level outline of the WSDL workflow as well as a conventional workflow that I have commonly been a part of for the last 20 years in this industry.

WSDL PIPING SPEC WORKFLOW

BENEFITS

- Single source data entry for both the issued spec, as well as the Plant3D piping software, eliminate data entry errors.

- Reduced checking and back checking time.

- Eliminate guess work – unified conventions between written spec and final Bill Of Materials

- Consistent format – ensures professional document deliverable

- Quick Change Mapping – To accommodate client standards, WSDL has developed a workflow that will allow automatic replacement of like items to suit client naming convention

WSDL PIPING SPEC WORKFLOW DIAGRAM

click on the image below to see how the issued spec gets created from the database ensuring consistent document syntax and formatting

CONVENTIONAL PIPING SPEC WORKFLOW

The conventional workflow shown below, has been my experience over the last 20 years. Inputting the data is one of my least favorite tasks, never mind the deciphering of the written spec to the requirements of the piping software and the areas left open for interpretation. As you can see there are 2 different data sources to begin with, which creates an extra checking process and greater margin for error.

Click on image to enlarge..